Essential Kitchen Knives

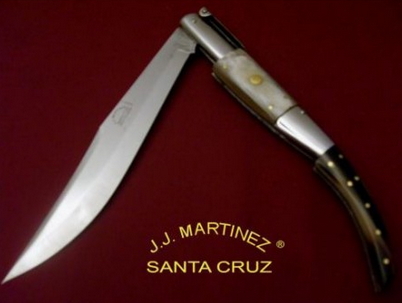

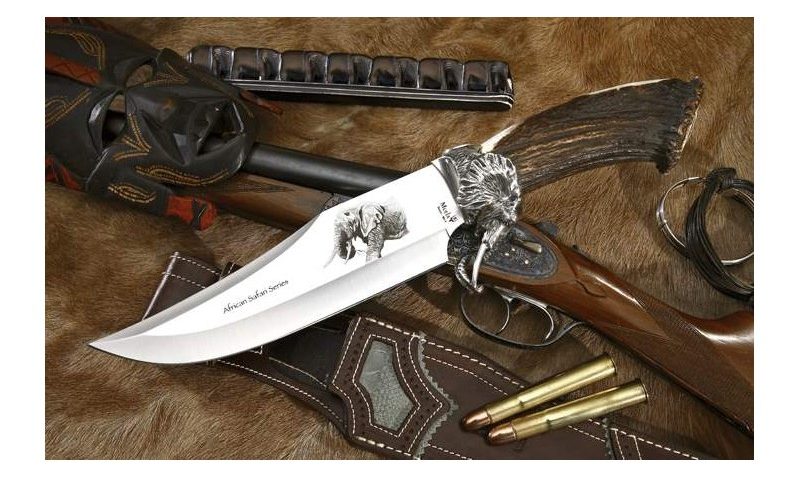

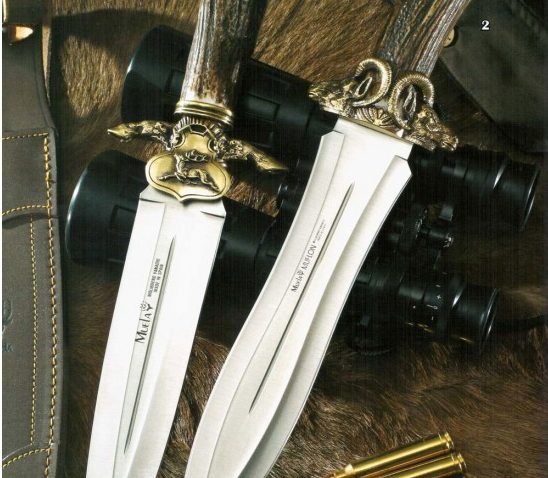

Indispensable Knives in the Kitchen Cooking is an art that thrives on skill, passion, and, of course, the right tools. Among these, knives hold a predominant place, being extensions of the chef’s hand that allow transforming raw ingredients into